High Speed Printing with Flexible Plates and Engraved Dies

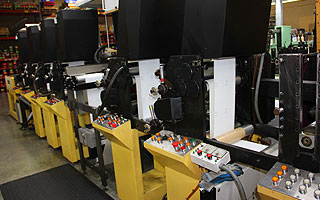

Flexography (often abbreviated “flexo”) is a form of rotary web letterpress printing that uses relief plates comprised of flexible rubber, low viscosity solvent, and water-based or UV-curable inks. The material is fed into the press from a roll. The image is printed as the material is pulled through a series of stations, or print units, each printing a single color. Various tones and shading are achieved by overlaying the four basic shades of transparent ink (magenta, cyan, yellow and black). If a spot color is needed (such as fluorescent, metallic, or a Pantone color), the ink hue is poured directly into one of the print units.

After the material is printed, it is pulled through another station on the press where it is cut with a cylindrical engraved die. This rotary die will cut out shapes as well as make perforations and slits. When labels are finished on a roll, the die cuts out the shape of the label but does not cut through the liner. The waste, or matrix, is lifted and removed from the liner, so it makes it easy to remove the label in end use.

Flexographic printing is usually used when printing large quantities of labels (over 15,000 feet of material per SKU). Due to the cost of printing plates, rotary die, and the time it takes to setup a job on a flexo press, short runs of labels are usually cost-prohibitive.

Flexographic Labels & Die Cutting